Fixed-bed reactors is commonly used in commercial-scale. Laboratory-scale fixed-bed reactors might be the first choice to screening new solid catalyst recipe, compare catalyst performance, etc. Pilot plant-scale fixed-bed reactors may briefly used for qualifying catalyst tested with commercial plant feeds. When scaling up or down, the shift of rate-limiting step might be the key factor.

Challenges in dissimilarity of mass throughput

A commercial reactor is usually designed to deliver high throughputs in order to maximize profits while minimizing total investment cost. Conversely, laboratory and pilot reactors are commonly used for experimentally investigating new phenomena and producing necessary information that is applicable or adaptable to the upscale design of new or improvement of existing commercial processes and its facilities. Utilization of laboratory and pilot units with low mass throughput is inevitable because of:

From the above reasons, it is logical that the flow regime inside laboratory, pilot plant and commercial reactors are significantly different. Generally, the flow regime of fluid can be classified into three types: laminar, transition, and turbulent flows. As expected, this flow-regime dissimilarity can significantly impacts the observed catalyst performance in a heterogeneous (solid-fluid) catalytic reactor. The following section will focus on the fixed-bed reactor as it is the most commonly used.

Challenges in Rate-controlling Mechanisms and Flow behavior

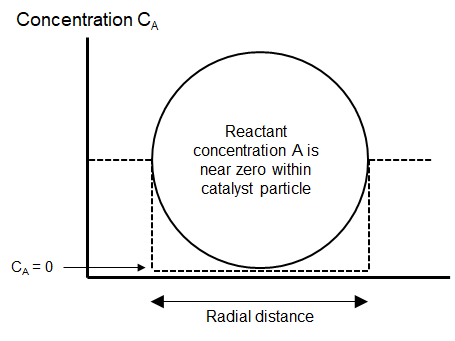

Laboratory and pilot reactors which are generally small in size and designed for low mass throughput frequently exhibit laminar-flow regime. As a result, the mass transfer resistance of the stationary film around the pellet is dominant and this becomes the rate-limiting step. The film resistance dramatically decreases when the flow regime becomes highly turbulent as typical in a commercial reactor. In other words, this shift from film diffusion rate controlling to pore diffusion rate or surface reaction controlling generally occurs when upscaling to a high-capacity commercial reactor.

Challenges in Rate-controlling Mechanisms and Operating Temperature

Another major difference between laboratory/pilot and commercial reactors is the effect of heat loss to the surrounding during operation. Due to a high surface area per volume of tubing and small piping as well as small quantity of reaction heat generation (or absorption) corresponding to low mass throughput, most laboratory and pilot reactors are run isothermally in practice. On the other hand, the corresponding effect of significant heat loss in a large-column commercial reactor with huge mass throughput is essentially negligible. Therefore, these reactors are generally designed and operated in adiabatic mode.

Generally the effect of temperature on the observed (or apparent) activation energy is investigated by carrying out experiments in laboratory reactor at sufficiently high fluid velocity to ensure reasonably fast film diffusion rate. Nevertheless, in the significantly high temperature range using catalyst powder, the film diffusion step would become rate-limiting and the observed global reaction resistance becomes more or less proportional to the external mass transfer film resistance.

The unintentional shift of the rate-controlling step over temperature variation represents another common pitfall in the design scale-up of fixed-bed reactors for highly exothermic and highly endothermic reactions. Due to the unavoidable difference in flow regimes between laboratory/pilot reactors operated isothermally and commercial reactors operated adiabatically, experimental data obtained in the lab reactor are useful for determining the true reaction kinetics as well as reaction scheme while those obtained in a small-scale pilot reactor are useful for investigating the conditions closer to the commercial unit. However, both types of data are often not sufficient for upscaling to a commercial adiabatic reactor. In practice, the commercial reactor is frequently designed at highly turbulent flow through packed bed of catalyst pellets in order to attain high throughput with acceptable pressure drop. Therefore, pore diffusion generally becomes the rate-limiting step. When adiabatic operation is adopted, an unintentional shift from pore diffusion control to film diffusion or more frequently intrinsic rate control is likely to occur, especially when there is large temperature difference between the inlet and outlet of catalyst bed. As a result, the designed reactant conversion and/or product selectivity may not be achieved if the facilities and reactor are designed without considering the above-mentioned shift. Another common pitfall is the reduction of catalyst size substantially in case of exothermic reaction in order to increase production rate by minimizing pore diffusion limitation. However, this may lead to runaway reaction after shifting to intrinsic kinetic rate limitation.

Estimating catalyst performance in commercial fixed-bed reactor

To successfully scale up from laboratory and pilot reactor to a commercial scale, it is necessary to understand the effect of flow behavior and temperature on the individual rate controlling step.

Case study

Let’s consider that case of a gas-phase fixed-bed reactor using a typically porous catalyst. The reaction is mildly exothermic and the proprietary catalyst was tested extensively in three different scales (laboratory, pilot and demonstration units) using the above-mentioned variety of experimental conditions.

Key Takeaway

Reference

https://www.hydrocarbonprocessing.com/magazine/2021/september-2021/catalysts/avoid-common-pitfalls-in-upscaling-catalytic-fixed-bed-reactors