By dedicating a small portion of your overall investment, our specialized team conducts an in-depth analysis to identify hidden inefficiencies. This focused effort often uncovers opportunities to reduce overall costs by 20–30%, thanks to optimized resource use, streamlined operations, and improved process flows.

Process synthesis is at the heart of designing scalable and efficient systems. It helps create optimized process flows, minimizes energy and material consumption, and supports sustainable practices. The result is a robust design that can be reliably scaled up from the lab to full production, ensuring both economic and operational benefits.

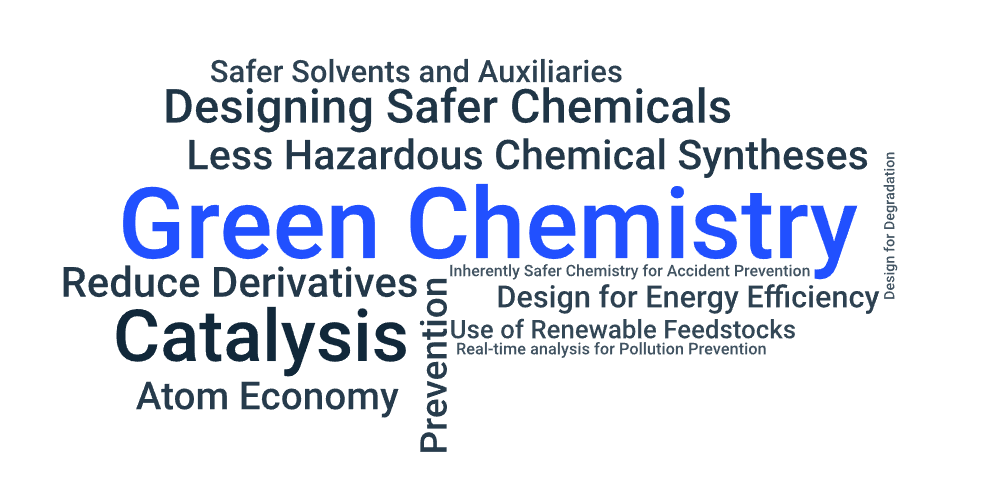

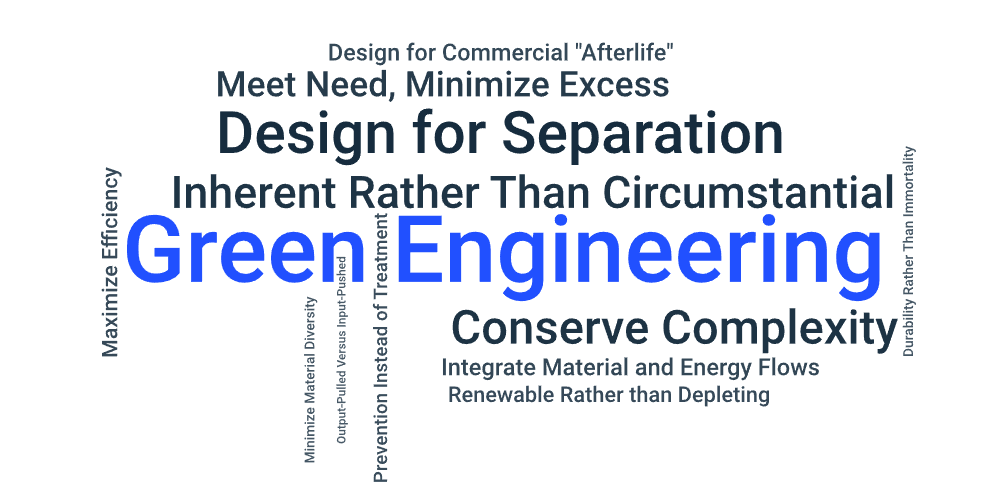

Our approach incorporates green chemistry and engineering principles to reduce environmental impact. By prioritizing renewable energy integration, low-carbon solutions, and waste minimization, we ensure that your process not only meets today’s efficiency standards but also positions your business for long-term environmental stewardship and regulatory compliance.

Our expertise spans multiple sectors, including pharmaceuticals, petrochemicals, renewable energy, specialty chemicals, and more. Any industry seeking to improve process efficiency, reduce costs, and implement sustainable practices can benefit from our integrated approach.

Our integrated methodology—combining process synthesis, digitalization, sustainability, and risk management—sets us apart. We focus on unlocking significant cost-saving opportunities while delivering robust, scalable designs that drive innovation and long-term growth.