Catalyst deactivation, the process whereby a catalyst loses its catalytic activity and/or selectivity, is a subject of vital importance in the development and optimization of catalytic processes. Its significance extends far beyond the boundaries of academic interest—it is a key concern in the industrial applications of catalysts, which form the bedrock of modern chemical manufacturing processes.

A catalyst, by definition, is a substance that can speed up a chemical reaction without being theoretically consumed by the reaction itself. This quality of persistence, the ability to facilitate numerous reaction cycles, is what makes catalysts so valuable in both natural and industrial processes. However, in reality, catalysts often undergo gradual performance degradation, leading to what is referred to as “catalyst deactivation.”

Understanding, predicting, and mitigating catalyst deactivation is a major challenge in the field of catalyst development. The choice of catalyst and the design of the catalytic process must consider the balance between catalyst activity, selectivity, and longevity. The cost and implications of catalyst replacement or regeneration need to be factored into the economic viability of the entire process.

As such, the study of catalyst deactivation is not just about understanding the mechanisms that lead to a decrease in performance. It’s a multidisciplinary field that touches on materials science, chemical engineering, kinetics, and even economic aspects. It is in solving the challenge of deactivation that we can continue to unlock the incredible potential of catalytic processes, driving forward countless industries and facilitating the creation of countless materials that underpin modern life.

Catalyst deactivation refers to the process in which a catalyst loses its effectiveness over time. It is a critical aspect of catalytic reactions, affecting both the economics and efficiency of industrial processes. The deactivation mechanisms can be generally classified into three main categories as Chemical, Mechanical, and Thermal:

Catalyst poisoning occurs when reactants, products, or impurities strongly adhere to the catalyst’s active sites. The rate of this process largely depend on the concentration and the adhering strength of the poison. Poisoning could occur quickly or slowly, and may or may not be reversible.

The mechanics of catalyst poisoning are multifaceted and can encompass a variety of phenomena such as:

It’s more effective to prevent poisoning through proactive purification of the reactant stream using equipment like scrubbers or guard beds (removing after catalyst is poison is difficult).

Theses chemical deactivation in catalysts can be minimized by managing the conditions under which reactions occur and by designing the catalyst suitably for its intended reactions

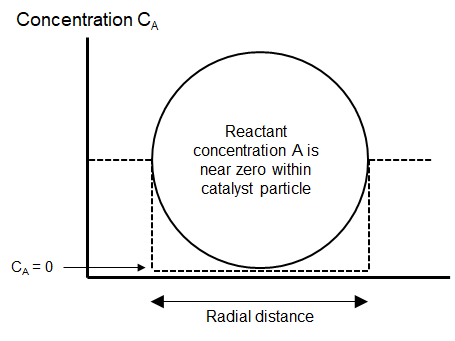

Fouling is the process where spcies from the fluid phase physically or/and mechnically accumulates on the catalyst surface. This accumulation can lead to a loss in activity due to blockage of the catalyst’s active sites and/or pores. In severe instances, it can cause catalyst particles to disintegrate and obstruct the voids in the reactor. A classic example of fouling is the mechanical deposition of carbon and coke in porous catalysts. Though it’s important to note that carbon and coke formation can also involve chemisorption of various types of carbons or condensed hydrocarbons, these deposits may behave as catalyst poisons. The differentiation between carbon and coke is somewhat subjective and traditionally tied to their source.The molecular structures of cokes or carbons produced in catalytic processes can vary significantly, and these variations are influenced by the type of reaction, the nature of the catalyst used, and the specific reaction conditions. Carbon is generally a byproduct of CO disproportionation, while coke results from the decomposition or condensation of hydrocarbons on catalyst surfaces, often comprising polymerized heavy hydrocarbons. However, the nature of coke can range widely – from high molecular weight hydrocarbons to primarily carbon substances like graphite. This depends on the conditions in which the coke was generated.There are several strategies to mitigate the formation of carbon deposits and coke, including:

Mechanical failure in catalysts can manifest in various forms, including:

While erosion is typically due to mechanical forces, the cause of fracture can be attributed to mechanical, thermal, and/or chemical stresses. For example, mechanical stresses in fluidized or slurry beds can stem from: (a) The collision of particles with each other or with the reactor walls. (b) The shear forces produced by turbulent eddies or cavitation at high fluid velocities. Moreover, the reduction of agglomerate size depend on several causes: (a)The intensity of the stress applied; (b)The inherent strength and fracture toughness of the agglomerate; (c) The size and surface area of the agglomerate

Recommended promising strategies to increase catalyst attrition resistance and strength involve:

Sintering is a process in which the particles of a catalyst coalesce at high temperatures, leading to a reduction in the surface area available for the catalytic reaction. It often occurs in metal catalysts used in high-temperature reactions. some factors impact to this mechanisms might be; (a) unwanted crystallite growth on catalytic surface area; (b) Loss of support area due to the collapse of the support structure; (c) Loss of the catalytic surface area resulting from the pore collapse on active phase crystallites; (d) Chemical transformations of catalytic phases into non-catalytic.

The growth of metal crystallites on a support could potentially involve a combination of all three sintering mechanisms (crystallite migration, atomic migration, vapor transport at high temperatures) operating concurrently. Still, the relative rates will hinge on the reaction conditions.

Several parameters predominantly affect sintering, including temperature, metal type, metal dispersion, the presence of promoters/impurities, and the surface area, texture, and porosity of the support, etc.

The key strategy to win sintering involves maximizing the catalytic activity to allow for operations at temperatures low enough to render sintering rates insignificant

Catalyst deactivation is examined various mechanisms lsuch as poisoning, fouling, mechanical failure, and thermal degradation. Each type of deactivation presents its unique set of challenges. The understanding of these processes can be preventative strategies. However, the battle against catalyst deactivation is a complex one, governed by a multiple factors. Thus, developers should consider not only their initial activity but also their long-term stability and resistance to deactivation. The longevity and efficiency of catalysts are crucial to the sustainability and economic viability of numerous industrial processes.