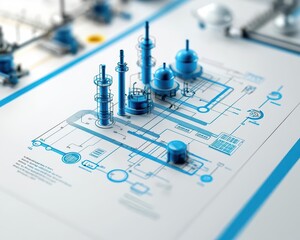

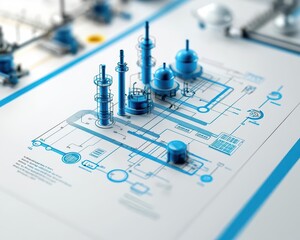

Process Design & Optimization is the engineering journey that transforms raw ideas—or under-performing legacy lines—into streamlined, scalable, and sustainable production assets. OSVARD guides small and mid-sized companies through every step: crystal-clear concept choices, bullet-proof basic design, practical detail, start-up confidence, and relentless post-commissioning refinement.

Material & energy balances. Our engineers crunch rigorous balances early, using high-fidelity simulation to pin down every kilogram and every kilowatt. You see exactly what each tonne of feed becomes, where each joule of heat goes, and which streams beg for recovery or recycle.

Process-flow development. Several flow-sheet scenarios often compete: a single large reactor versus parallel trains; distillation against liquid–liquid extraction; heat-pump integration versus classic steam reboil. We model, cost, and rank them so you choose on hard numbers, not hunches.

Equipment sizing & selection. Reactors get the right residence time and mixing regime; columns the right height, area, and internal style; pumps and compressors the right margin—not a millimetre more in capex than needed, yet never starved in real operation.

Early safety & compliance. Relief paths, inerting strategies, emission limits, and wastewater specs are embedded from day one. Retrofitting EHS later is expensive; designing it in is smart business.

Piping and Instrumentation Diagrams turn the flow sheet into an operable plant. Every instrument tag, loop logic, start-up vent, and sample point is defined. OSVARD facilitates HAZOP studies at this stage—catching operability snags while they’re still pixels, not welded steel.

The resulting Basic or FEED package contains:

Issue-for-design PFDs and P&IDs

Preliminary equipment datasheets

Utility and battery-limit summaries

±30 % capital and operating cost estimate

Project execution roadmap through mechanical completion

This package secures board approval, vendor budget quotes, and—in many cases—investor funding.

OSVARD can carry the baton into detailed engineering and construction support. We firm up instrument ranges, valve sizing, control-panel layouts, skid modularisation, and installation drawings. Vendors build from our signed-off datasheets; inspectors test against our acceptance criteria; your commissioning team inherits a coherent, traceable design.

Even the best-designed facility needs tuning in the real world. OSVARD stays on to shepherd:

Performance test runs confirming capacity, yield, utilities, and emissions.

Operator coaching so shift crews hit targets and spot deviations early.

Failure-mode reviews leading to spare-parts strategies and maintenance workflows.

We integrate historian tags or add missing sensors, then benchmark against design KPIs and industry peers. Gaps become easy targets: excess steam per tonne, off-spec rework, chronic bottlenecks.

Capacity climbs often hide in plain sight. A tray upgrade, compressor intercooler, or smarter batch schedule can unlock 10–15 % throughput without new buildings.

Model-predictive controllers, inferential quality analysers, and heat-tariff optimisation loops squeeze extra margin with little—or zero—capex.

Pinch re-runs, waste-heat recovery, heat-pump retrofits, or catalyst changes keep energy intensity falling and sustainability KPIs rising.

Optimization is never once-and-done; OSVARD establishes quarterly or annual health checks so your plant evolves with feed costs, energy prices, and customer demands.

Faster scale-up: Lab idea to cash-flowing production without costly pilot dead-ends.

Higher margins: 5–20 % cuts in utility or raw-material bills are common within the first improvement cycle.

Reliability & quality: Fewer emergency trips, tighter spec windows, happier customers.

Regulatory confidence: Designs that meet—or exceed—current and future environmental rules.

Team upskilling: Your engineers gain simulation, integration, and optimisation know-how by working shoulder-to-shoulder with ours.

OSVARD blends hard-nosed engineering with modern digital tools to give your process a razor-sharp competitive edge—today and throughout its life. Let’s design it right, start it strong, and keep it getting better.