Moving a process from a 500-mL flask to a 5 000-L reactor is not about multiplying ingredient weights. Geometry, fluid flow, heat removal, safety margins, and even business economics all shift in non-linear—and sometimes counter-intuitive—ways. Below are the six pillars OSVARD always reviews before any scale-up step.

A vessel’s volume grows faster than its surface area, so the ratio of area-to-volume falls off as equipment gets bigger. In the lab you could whisk away reaction heat through a thin glass wall; in a plant reactor hot spots may appear because the surface available for cooling has scarcely kept pace with the bulk. Our engineers often add jackets, coils, or extra baffles—not simply “more volume”—to restore the right thermal balance and mixing profile.

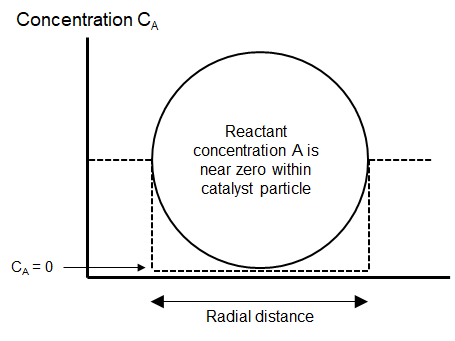

What was fully turbulent with a magnetic stir bar can become laminar pockets in a large tank if impeller power per volume dips too low. To keep reaction kinetics or oxygen transfer on target, we match dimensionless numbers such as Reynolds, Power/Volume, or Tip Speed, and we select impeller types (multi-stage, high-shear, or sparged) that maintain uniformity at scale.

Heat transfer coefficients seldom scale linearly. A reaction that felt “trivial” to cool in a flask may threaten runaway in production. We run pilot tests or CFD models to verify heat-transfer rates, then size jackets, external exchangers, or recycle loops accordingly. Sometimes the fix is as simple as increasing agitation; other times, adding surface area is the only safe route.

Lab glass, Hastelloy coupons, or syringe filters are rarely practical at the tonne level. We evaluate corrosion rates, mechanical stresses, cleanability, and cost to pick fit-for-purpose alloys, seals, filters, and pumps. A bench-top filter cake that clears in minutes can demand an entirely different technology—centrifuge, belt filter, or press—when flows are 1 000× larger.

Bigger volumes mean greater stored energy and longer time constants. Control loops that cycled every ten seconds in the lab might now take ten minutes to respond. OSVARD performs fresh HAZOP studies, re-tunes controllers, and adds instrumentation so operators (or APC systems) can manage those slower dynamics without drifting outside safe limits.

Grams of exotic catalyst may cost pennies in R&D but millions at scale. Likewise, litres of solvent waste turn into truckloads that trigger environmental permits. Early techno-economic analysis and regulatory mapping keep the business case intact and prevent late-stage surprises.

Whenever possible we mirror the final flow pattern, control philosophy, and materials right from the pilot stage. If the destination is a continuous plant, we prototype continuous—even at the litre scale. This foresight turns scale-up from a leap of faith into a well-lit staircase.

Scaling is part physics, part creativity, and wholly unforgiving of shortcuts. By addressing geometry, mixing, heat, materials, control, and economics together, OSVARD guides clients from lab bench to production line without the usual stumbles. Plan early, test smart, and let scale amplify your success—not your headaches.