The important point frequently received from customers, when new or existing reactor designed, reconfigured, or replaced with new catalysts, is how to totally use catalyst performance during operation.

Scienifically, the catalyst performance in commercial-scale reactor depends on what rate-limiting step controls the overall reaction rate.

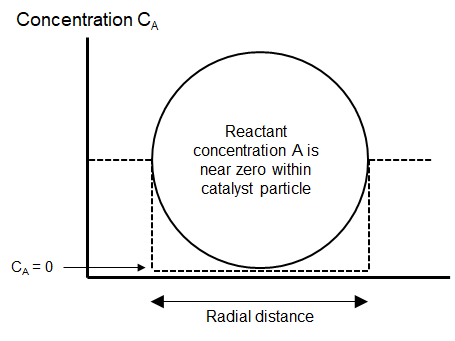

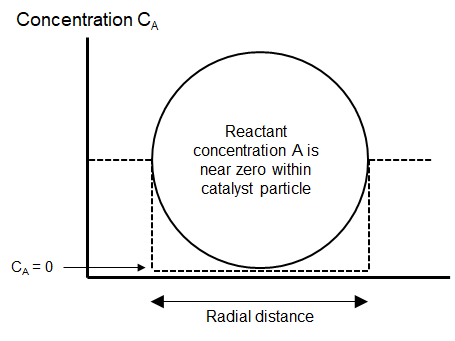

From the figure, the rate of film diffusion from bulk fluid to catalyst surface is slowest step and the overall rate of reaction is controlled by external mass transfer. In this regime, reactants are rapidly converted to products as fast as they arrive at the external surface of the catalyst. Consequently, the concentration of reactants is near zero at external interface of the catalyst and bulk fluid that it means poor utilization of catalyst. In other words, practically, chemical reaction engineer may “avoid” to design reactor operated in film-diffusion limitation.

The efficiency should be over 95% that it means the resistance due to film diffusion being less than 5% of the resistance due to chemical reaction. The main parameters influencing the efficiency may be included:

Recommedation