Hyperloop One, initially a high-profile venture, raised over $450 million and constructed a small test track near Las Vegas. The company informed the remaining employees overseeing asset sales that their employment would end by December 31. Hyperloop One captured public interest with its promise of a revolutionary transportation system, an idea originally proposed by Elon Musk in 2013. However, it struggled with internal issues, including leadership controversies and legal problems involving its founders and directors. Even though no one has commercialized a large-scale hyperloop system , the idea still really excites entrepreneurs. A bunch of companies like Hardt Hyperloop, Hyperloop Transportation Technologies, and Swisspod Technologies are busy making their own versions of hyperloop prototypes, showing that people are still super into this high-tech transport idea.

Carbon Capture and Storage (CCS) is a technology aimed at reducing carbon dioxide (CO2) emission. The basic concept involves three key steps:

In the context of separating CO2 from other gases (like in flue gas from power plants), The below equation can represent

“The minimum energy required for the separation process. There’s no beating this, no matter what technologies we develop. It can never cost less energy than this”

The separation process efficiency is often limited by thermodynamic constraints, and the energy required depends on the difference in CO2 concentration between the two states.

The logarithmic nature of the equation implies that as you try to increase the purity of CO2 (i.e., increasing P1/P0), the energy required increases significantly. This represents the increasing difficulty and energy expenditure required to achieve higher levels of CO2 concentration

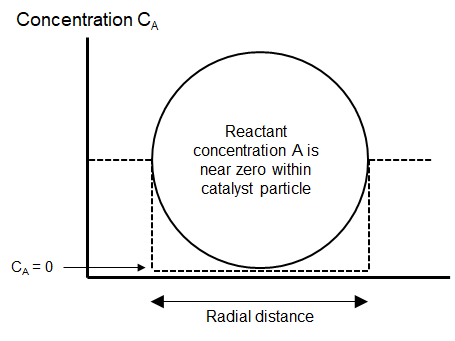

DAC systems are complex. They require mechanisms to filter large volumes of air to extract relatively small concentrations of CO2 (about 0.04% of the atmosphere). Moreover, DAC typically require sorbents, which selectively bind to CO2. Additionally, once the CO2 is captured, it must be released from the sorbent, which usually requires energy for regenarating process.

The separation of CO2 from air is a thermodynamically demanding process. The low concentration of CO2 in the atmosphere means that a large amount of air must be processed to extract a useful amount of CO2, which inherently requires a lot of energy. This is a fundamental challenge rooted in the laws of thermodynamics.

The energy required for running DAC systems primarily comes from two sources:

This energy demand makes DAC a high-energy process, and if the energy used is not from renewable sources, the overall carbon footprint of the DAC process can be counterproductive.

Due to the high energy requirements the operational costs of DAC are high. This makes it an expensive method for carbon capture compared to other approaches like capturing CO2 from industrial sources, where CO2 concentrations are much higher.

The views and opinions expressed in this Linkedin article are solely my own and do not represent the views or opinions of my current employer. This article is a personal reflection and does not involve any proprietary or confidential information from my current company. Any similarities in ideas or concepts presented in this article to my current company’s work are purely coincidental.