Modern factories already pulse with sensors, controllers, and alarms. Yet most still rely on basic PID loops and manual tweaks that leave efficiency—and profit—on the table. OSVARD’s Data Analytics & Control service adds a brain to that nervous system, blending process-control know-how with data science so your plant can see trouble coming, adjust in advance, and run closer to its true limits.

Conservative set-points — Operators keep temperatures or flows below optimum to avoid overshoot.

Loop interactions — Several PIDs tug on each other, causing slow swings in quality.

Hindsight alarms — A sensor drifts for hours before anyone notices, leading to off-spec batches.

These gaps cost energy, throughput, and operator time. Advanced analytics can close them—fast.

Anomaly Detection

Algorithms watch live trends and flag subtle pattern shifts before alarms trip, catching fouling sensors or equipment wear early.

Performance Dashboards

Real-time KPIs compare current efficiency to an ideal model, showing exactly where wasted power or lost yield hides.

Model Predictive Control (MPC)

A data-driven model predicts the future, then adjusts multiple valves and dampers together—keeping purity, rate, and safety in tight balance.

Real-Time Optimization (RTO)

Hourly mini-economic optimizations nudge set-points toward maximum profit, factoring in feed prices, utility costs, and quality specs.

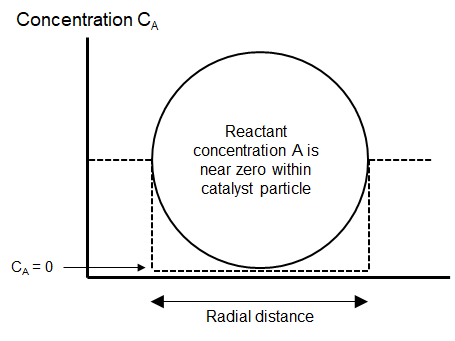

Soft Sensors

Virtual analyzers infer hard-to-measure qualities—such as composition or molecular weight—from easy readings, enabling near-instant quality control.

Diagnose the Pain Points

We review alarms, operator logs, and variability to pinpoint where better control will pay off.

Mine the Data

High-frequency historian data reveal process dynamics; system-identification tools turn those dynamics into usable models.

Design & Test

Advanced controllers and analytics run first on a digital twin or simulation, proving safety and benefits long before plant trials.

Deploy & Train

We roll out changes in phased steps, coach operators, and fine-tune until the new system earns their trust.

Fertilizer Reactor — MPC cut temperature swings by 50 %, raising conversion and easing equipment stress.

Distillation Train — An inferential purity sensor plus APC let operators push 8 % more feed without off-spec risk—millions in added revenue.

Polymer Batch Line — Soft-sensor-guided control boosted on-spec batches from 70 % to 95 %, slashing waste and rework.

Compressor Health — Predictive logic eased load when vibration trended high, preventing an emergency shutdown and two days of lost production.

Higher Throughput — Run nearer to constraints without crossing them.

Steadier Quality — Tight control keeps specs on target, reducing rework.

Lower Energy — Optimized set-points trim power and steam use 5–10 %.

Safer Operation — Early warnings and graceful mitigations cut unplanned trips.

Operator Empowerment — Dashboards and advisories turn data into clear, actionable guidance.

“Let the data drive—your people steer.”

Ready to let your plant think ahead? OSVARD’s Data Analytics & Control team can bring AI-level foresight to your operations, quickly and safely.